Drill Bits and Dynamite....Part Fifteen...Sea to Sky Segment One....Cut 5

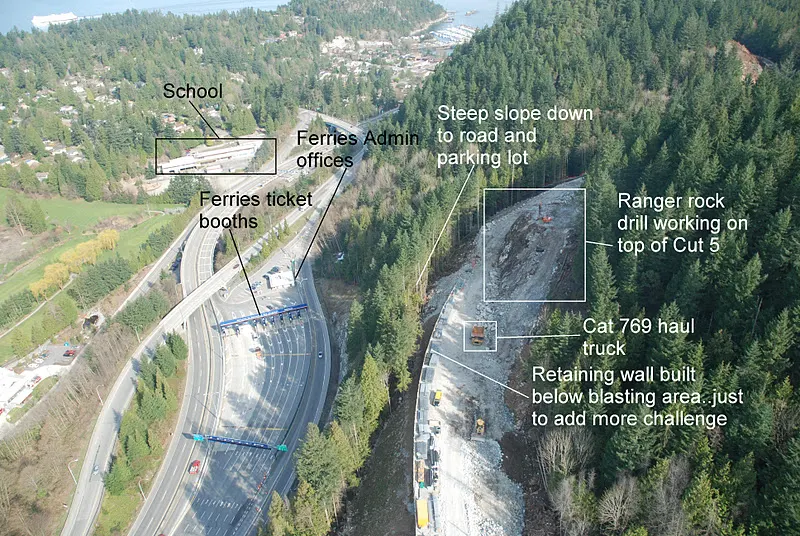

Cut 5 wasn't the biggest or the nastiest piece of blasting work on the Sea to Sky project. It was however perched directly above the ferry terminal ticket booths at Horseshoe Bay in West Vancouver...all 40,000 cubic meters of it.

The usual way to blast, is to start at the "free'" face and send the blast outwards. As powerful as the explosives are, they have their limits on what can be accomplished. Shooting to a "free" face, allows the rock to easily move away from the wall behind. Blasting to a "free" face also greatly minimizes the vibration in the ground when the shot is fired...and offers much more control of fly-rock.

The way that Cut 5 was situated, prevented us from doing things the usual way. There were two reasons for this. One was that the ticket booths were in the direct line of fire, if we shot away from the obvious free face. The second reason was that the flat area in front of Cut 5 was too narrow to hold any sizable shot that would land on it. That means ...if we were successful in controlling the blast perfectly...the bench below couldn't hold all the broken, falling rock. The resulting avalanche of explosives driven rock would cascade down to the road and terminal parking lot below. That's not a career advancement move.

You would think that deciding to take a safer approach to the problem would be a slam dunk....well...you'd be wrong.

Because the entire project was a fixed price bid job, any time that money could be saved, or schedule sped up...that was the way to go. The argument in the planning for Cut 5, was that several of the bosses wanted to drill it big, hit it hard and then apologize for the mess and damages...while penciling in profits on the production side.

The real world issue was that BC Ferries wasn't going to tolerate any avalanche of rock burying their parking lot and customers, so that a good profit could be had.

The real world issue is that the blaster in charge is legally responsible for the results of his work...even if his powerful boss says to do it ...or else.

The blaster can't knowingly do the wrong thing, just because his boss says to go ahead.

The real world issue ( cont'd ).... is that all the blasters were locals and proud of their individual safety records. We had a pact to do everything humanly possible to do no damage to the surrounding structures...and certainly to avoid injuries to anyone and everyone.

The protection of a mega-corporation doesn't really exist out in the real world....although in the boardroom..in the pursuit of profits...it certainly does get used as bait.

I consulted with Gary Anderson from Metro Blasting on several techniques to use on Cut 5. I have huge respect for Gary, and also Wayne Verwey from Sierra Drilling and Blasting...both guys have tons of experience doing great work in tough West coast rock conditions. Whenever I needed useable info on working in tricky areas, I always tried to run the ideas past one or both of these guys.

We ended up starting the blasting at either end of the outcropping and shooting North/South...as opposed to firing the rock right at the parking lot. We blasting out a hole in behind the free face and this allowed us to, in effect shoot the front face "backwards" and away from the ferry terminal. This took a bit more time, and some fancy blast patterns and loading techniques. In the end, not one rock went over the edge, save for one lone softball sized nugget that fell into a closed lane.

The process of firing a Cut 5 blast was a unique experience in itself.

Of course the company traffic people could manage to close off all the roads when needed, but the ferry terminal offered new challenges.

For 100% safety , we couldn't have anyone in the parking lot, ticket booths or ferry administration offices when we blasted at Cut 5. This meant temporarily closing the terminal and evacuating the ferry personnel.

That's not something that the BC Ferries managers were real excited about doing.

To get a shot off successfully was a major undertaking.

1. We were only allowed to close the Upper Levels and Highway 99 for very short times and only on a specific schedule. Sometimes we were only allowed a 5 minute total closure.

2. We had to get the approval of BC Ferries to blast...only when it suited them to close the booths and evacuate.

3. We had to empty out the parking lot of ferry users, and then close the booths.

4. The Upper Levels was closed to prevent new cars from coming into the terminal.

5. The traffic people, plus some of our blasting crew, shut down all the highway on/off ramps in the surrounding area.

6. Confirm that all the BC Ferries people are gone. A phone call to a ferries manager confirms this...plus a quick check with our own eyeballs to double check.

7. Empty ticket booths, offices, parking lot and highways.

8. Radio to the blaster with the firing control box to start the countdown to pushing the button.

9. I stayed below to watch for and track any incoming rock.

10. Click....boom.....a big thud...the ground shakes....I can hear the rock falling into a pile....none of it is hurling over the trees towards me ( that's good...I can keep my job for another day )

The ferry managers got into the swing of things after a few blasts. I think they were a bit nervous at first about the whole thing...both the dangers of blasting....plus the possible schedule disruptions. I had two different managers that I was in contact with to arrange the booth closures. One was very uptight and wasn't having any fun at all ( sounded just a tad miserable ) ...the other person was friendly and very helpful. A few times we re-scheduled blasts to coincide with the "friendly" manager's shifts...especially if we needed an extra favor or two. The results were that same...it was just easier and removed some of the stress...instead of adding more.

In many it ways it was amazing that the whole thing went as well as it did. With all the various groups that had to get along...and cooperate...on a tight schedule..it wasn't so bad after a regular routine developed.

The ferries people and their schedule were one of the biggest bottlenecks..( not their fault...just the nature of the biz ) If we ran late in our ten minute window of opportunity, the ferry management had the authority to re-open the ticket booths to get traffic moving to the boats. ( and delay our blast 24 hrs...with full guarding of the loaded shot ) That never had to happen...but we did have some closures that ran closer to fifteen minutes ( that's when I ask the yelling person on the phone to call the project manager ) Then quickly phone the project manager to tell him that an unhappy customer is going to call in a sec.

To add to the drama, the walls crew decided to build an MSE ( mechanically stabilized earth ) wall below Cut 5.

Now, gravity being what it is...constant and always pulling down ...that lead to a few loud debates over how smart it was to build an expensive and somewhat delicate structure below a blasting operation.

The walls crew needed to build the wall to keep working and get ahead on their own schedule...and we on the blasting crew didn't want to have more stuff to hit. We lost that cat-fight and the wall went up. It got clobbered a few times with blast rock falling on it...and then repaired.

I guess that on a large bid project...constant forward motion is the main driver of decision making.

The usual way to blast, is to start at the "free'" face and send the blast outwards. As powerful as the explosives are, they have their limits on what can be accomplished. Shooting to a "free" face, allows the rock to easily move away from the wall behind. Blasting to a "free" face also greatly minimizes the vibration in the ground when the shot is fired...and offers much more control of fly-rock.

|

| Loading a Cut 5 pre-shear blast |

|

| The roll of green stuff that looks like garden hose...is actually a very high strength explosive |

The way that Cut 5 was situated, prevented us from doing things the usual way. There were two reasons for this. One was that the ticket booths were in the direct line of fire, if we shot away from the obvious free face. The second reason was that the flat area in front of Cut 5 was too narrow to hold any sizable shot that would land on it. That means ...if we were successful in controlling the blast perfectly...the bench below couldn't hold all the broken, falling rock. The resulting avalanche of explosives driven rock would cascade down to the road and terminal parking lot below. That's not a career advancement move.

You would think that deciding to take a safer approach to the problem would be a slam dunk....well...you'd be wrong.

Because the entire project was a fixed price bid job, any time that money could be saved, or schedule sped up...that was the way to go. The argument in the planning for Cut 5, was that several of the bosses wanted to drill it big, hit it hard and then apologize for the mess and damages...while penciling in profits on the production side.

The real world issue was that BC Ferries wasn't going to tolerate any avalanche of rock burying their parking lot and customers, so that a good profit could be had.

The real world issue is that the blaster in charge is legally responsible for the results of his work...even if his powerful boss says to do it ...or else.

The blaster can't knowingly do the wrong thing, just because his boss says to go ahead.

|

| Looking north at Cut 5....standing on the MSE wall |

The protection of a mega-corporation doesn't really exist out in the real world....although in the boardroom..in the pursuit of profits...it certainly does get used as bait.

I consulted with Gary Anderson from Metro Blasting on several techniques to use on Cut 5. I have huge respect for Gary, and also Wayne Verwey from Sierra Drilling and Blasting...both guys have tons of experience doing great work in tough West coast rock conditions. Whenever I needed useable info on working in tricky areas, I always tried to run the ideas past one or both of these guys.

We ended up starting the blasting at either end of the outcropping and shooting North/South...as opposed to firing the rock right at the parking lot. We blasting out a hole in behind the free face and this allowed us to, in effect shoot the front face "backwards" and away from the ferry terminal. This took a bit more time, and some fancy blast patterns and loading techniques. In the end, not one rock went over the edge, save for one lone softball sized nugget that fell into a closed lane.

The process of firing a Cut 5 blast was a unique experience in itself.

Of course the company traffic people could manage to close off all the roads when needed, but the ferry terminal offered new challenges.

For 100% safety , we couldn't have anyone in the parking lot, ticket booths or ferry administration offices when we blasted at Cut 5. This meant temporarily closing the terminal and evacuating the ferry personnel.

That's not something that the BC Ferries managers were real excited about doing.

To get a shot off successfully was a major undertaking.

1. We were only allowed to close the Upper Levels and Highway 99 for very short times and only on a specific schedule. Sometimes we were only allowed a 5 minute total closure.

2. We had to get the approval of BC Ferries to blast...only when it suited them to close the booths and evacuate.

3. We had to empty out the parking lot of ferry users, and then close the booths.

4. The Upper Levels was closed to prevent new cars from coming into the terminal.

5. The traffic people, plus some of our blasting crew, shut down all the highway on/off ramps in the surrounding area.

6. Confirm that all the BC Ferries people are gone. A phone call to a ferries manager confirms this...plus a quick check with our own eyeballs to double check.

7. Empty ticket booths, offices, parking lot and highways.

8. Radio to the blaster with the firing control box to start the countdown to pushing the button.

9. I stayed below to watch for and track any incoming rock.

10. Click....boom.....a big thud...the ground shakes....I can hear the rock falling into a pile....none of it is hurling over the trees towards me ( that's good...I can keep my job for another day )

The ferry managers got into the swing of things after a few blasts. I think they were a bit nervous at first about the whole thing...both the dangers of blasting....plus the possible schedule disruptions. I had two different managers that I was in contact with to arrange the booth closures. One was very uptight and wasn't having any fun at all ( sounded just a tad miserable ) ...the other person was friendly and very helpful. A few times we re-scheduled blasts to coincide with the "friendly" manager's shifts...especially if we needed an extra favor or two. The results were that same...it was just easier and removed some of the stress...instead of adding more.

In many it ways it was amazing that the whole thing went as well as it did. With all the various groups that had to get along...and cooperate...on a tight schedule..it wasn't so bad after a regular routine developed.

The ferries people and their schedule were one of the biggest bottlenecks..( not their fault...just the nature of the biz ) If we ran late in our ten minute window of opportunity, the ferry management had the authority to re-open the ticket booths to get traffic moving to the boats. ( and delay our blast 24 hrs...with full guarding of the loaded shot ) That never had to happen...but we did have some closures that ran closer to fifteen minutes ( that's when I ask the yelling person on the phone to call the project manager ) Then quickly phone the project manager to tell him that an unhappy customer is going to call in a sec.

|

| Working on the ditch-line at Cut 5...Larsen Creek Bridge in the background |

|

| Cut 5 looking towards Cut 4 |

Now, gravity being what it is...constant and always pulling down ...that lead to a few loud debates over how smart it was to build an expensive and somewhat delicate structure below a blasting operation.

The walls crew needed to build the wall to keep working and get ahead on their own schedule...and we on the blasting crew didn't want to have more stuff to hit. We lost that cat-fight and the wall went up. It got clobbered a few times with blast rock falling on it...and then repaired.

I guess that on a large bid project...constant forward motion is the main driver of decision making.

|

| North side of Cut 5...excavator swinging blast mats onto a ditch-line shot |

|

| Cut 5 looking towards Larsen Creek Bridge |

|

| Three Cat 769 haul trucks parked at Cut 5 |

|

| Starting to look at bit more finished and organized |

|

| Looking from Cut 5 to Cut 4 |

Comments

Post a Comment