Kiewit Built Defective MSE Retaining Walls on the Sea to Sky Highway

de·fec·tive

dəˈfektiv/

adjective

- 1.imperfect or faulty.

"complaints over defective goods"

synonyms: faulty, flawed, imperfect, shoddy, inoperative, malfunctioning, out of order, unsound; More

antonyms: perfect - lacking or deficient.

synonyms: lacking, wanting, deficient, inadequate, insufficient

"these methods are defective"

This going to be a photo and comment post about the Kiewit built MSE ( Mechcanically Stabilized Earth ) walls on the 2010 Sea to Sky highway project.

Just to keep things simple and move along quickly.

I became curious about the Sea to Sky MSE walls in 2013, after reading about the problems on the CalTrans 405 Freeway project. Kiewit built MSE retaining walls along side the freeway that started to show signs of distress immediately after being built.

http://www.dailynews.com/

I had worked on the S2S project from the beginning in 2006 to 2008 as a blasting superintendent. Our crew did all the rock blasting in preparation for the MSE wall construction. I had a front row seat to all the planning meetings, and the work that followed.

When I went back to visit one of the first MSE walls built in the West Vancouver section of the S2S job, I was shocked at the miserable condition it was in. The interesting part of the wall can only be accessed by a hike down the front that risks life and limb. I knew where to go, because my crew drilled and blasted all the access to the wall site.

Here are some low res images of the original construction from 2006. MOT wall number 9450R, Holding up the Upper Levels section of Hwy99.

|

| Excavating blast rock from the future site of MSE wall 9450R at Upper Levels highway |

|

| Foundation work for wall 9450R |

|

| The original bridge ( upper left ) was demolished by a contractor when the MSE wall came up to height |

|

| Carpenters doing the form work for the foundation of MSE wall 9450R |

|

| Foundation work for wall 9450R. Looking west towards approach to Horseshoe Bay ferry terminal |

|

| Aerial view of part of MSE wall 9450R with part of the old Upper Levels Highway on the right |

Here are images from trips to the same wall in 2013/2014

|

| That's me bush-wacking down to the bottom of the wall to get the shots. |

The BC Ministry of Transportation describes this as merely "cosmetic"

|

| Horizontal bulge and displaced concrete panels in MSE wall 9450R on Upper Levels Highway ( Hwy 99...Sea To Sky ) |

|

| Water drainage issues causes many problems...backfill settlement and the introduction of road salt to the steel reinforcing wires behind the wall. In this area of 9450R, the drain water has been bypassing the pipes and running through the wall. |

|

| Add caption |

| |

| Some sort of dog's breakfast repair going on here during original construction process. |

Wall 9471A at Pasco Rd. looks very nice.

Proper batter ( laid back a bit...and very consistently so ) Nice alignment of concrete panels, even gaps...all looks very good. It also has the job of holding up the new section of the S2S highway.

However, MOT and Kiewit insist that simply by reviewing the paperwork, they discovered that faulty rebar or horizontal straps were installed...in only one particular section.

( see below for Sept 8/ 2015 update with link to MOT inspections and communications regarding reasons for Brandywine Falls/ CNRail overpass repairs )

Most of the MSE wall repairs that I have researched in North America, have had obvious external signs of strain. The buckling, bulging or outright collapse has always got the attention of highway engineers.

Of the 219 MSE walls on the 130km long project, this wall was deemed to have invisible defects buried in behind the good looking facing.

Do I have photos of that area under construction? Yes!

Flash forward to the summer of 2015, and the concrete panel wall 9471A is getting completely rebuilt. The original panels are getting drilled and long soil nails are getting installed ( 10 meters ? I guess )

Then a heavy rebar cage is getting installed in front of the old facing. Either shotcrete or a formed face will be installed over the rebar cage ( not complete on Aug. 22/ 2015 )

Here is a drawing of a soil nailing set-up ( not too much different from rock bolting )

|

| Shows the drill rig and steel soil nails through the wall and into earth/soil/rock in behind to anchor the wall face |

These are July 2015 images

|

| Soil nails driven through the Pasco Rd MSE wall to repair a defect in the buried steel mesh behind the wall.....says MOT spokesperson |

|

| Good looking Pasco Rd MSE wall is getting expensive repairs, while the visibly defective 9450R gets nothing. BC MOT says that the problems with 9450R are merely cosmetic and do not affect the expected 75 yr life span. |

Ladies and gentlemen...Todd Stone vs some pretty basic questions from Claire Trevena

Next...... Todd Stone and "mitigative work" and defending Kiewit. Note....he gets the number of retaining walls on the project....wrong. There's 219 walls on the S2S highway project.

And images from August 2015 MSE wall rebuild

|

| Thick rebar steel cage to support a new concrete facing on the Pasco Rd MSE wall |

|

| As an educated guess, I would say the retail cost of repairing the Pasco wall, including inspection, engineering, management, office costs, traffic control, materials is in excess of 2 million bucks |

End of Sept 20/2015 Pasco update photos

|

| Deformed MSE wire wall on Sea to Sky Highway near the faulty Pasco Road MSE wall. |

|

| Perhaps, as Minister Todd Stone and Kiewit would say...this is only a "cosmetic defect." Did we get a price break because we got cosmetically defective work? Why should BC tolerate cosmetically defective work on our major highways? |

|

| I would guess that the bent wires in this Sea to Sky MSE wall must be getting stressed by being bent at that angle...will it last the expected 75 yrs? Was it poorly built that way...or has 5 yrs of down pressure pushed it out? |

|

| Wall 78 a few hundred meters from Pasco Rd. Overgrown with vegetation. Only a few years old |

I'll post more images as the job progresses.

Brandywine Falls area, CN Rail overpass....HWY99 ( Sea to Sky )

I was coming back from a road trip to the interior, and decided to stop and see what was happening here.

Very stealthy setup...hard to see anything from the highway.

Unfortunately for Kiewit and MOT, I was the only guy to stop and get out of my car with a camera.

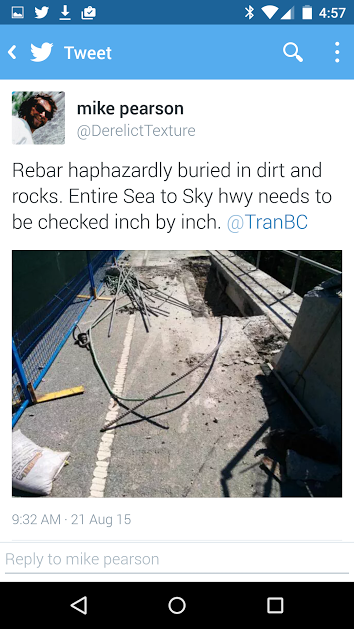

The "Safety First"..."Don't Walk by an Unsafe Act"...."Nobody Gets Hurt" Kiewit....had left and open excavation on the edge of the roadway. It was the perfect "gringo trap"....long and deep and full of sharp ends of cut off rebar steel.

So, despite the fact that I wanted to come back with a bigger camera, I decided to alert MOT and PKS to the killer hole.

I'm still waiting for an official response from Kiewit.

The open excavation also held a mystery.

Why, oh why is steel rebar buried in rocks and dirt??? ( it's supposed to be encased in concrete )

Why does the rebar in the ground look like it was just tossed in there, instead of meticulously laid out???

Minister Todd Stone said that they were doing some "mitigative work"....well doesn't that look like a total rebuild down there by the tracks? Old concrete sectioned out...new DCP bolts getting installed....new wall or wall facing going up.

The entire support system for the rail overpass looks to be getting replaced. Mitigative work....remember that one.

|

| Unrestricted access to an open excavation |

|

| A mishmash of rebar buried in dirt and rocks...at a CN Rail overpass...still waiting for an explanation |

|

| Looks like a nice lawsuit sitting there doesn't it? |

|

| In the year 2015, this is a pretty dumb move. If a cyclist crashed into that...I can't imagine the millions it would cost to settle the lawsuit. |

|

| Complete rebuild of the support structure ( mitigative work ) |

|

| I've heard from various sources that the original DCP anchors failed due to the voids in the back-fill. Two semi-truck loads of pressure grout failed to fix the issue |

Sept. 7 2015 email from MOT in response to me notifying them of the open excavation and unchallenged access to it. I sent the same photos as you have here.

Viz screen and concrete "no post" barriers separate the active lane from the edge....but no barriers, tape or signage to prevent walkers and cyclists getting to the open hole and rebar.

My original email to MOT

Hello Deborah

The photos enclosed were taken at 2 pm on Aug 19/ 2015.

The photos enclosed were taken at 2 pm on Aug 19/ 2015.

The first thing we need to talk about and fix asap...is the unprotected/ unmarked hole in the road surface.

Any walker/ hiker or cyclists has unimpeded access to that dangerous and carelessly placed excavation. That's a massive lawsuit just sitting there staring at the contractor and MOT.

Any walker/ hiker or cyclists has unimpeded access to that dangerous and carelessly placed excavation. That's a massive lawsuit just sitting there staring at the contractor and MOT.

So, if that hole and pile of rebar exists there this a.m. then push the panic button now.

A review and punishment is in order for that new low in unprofessional work.

Then...

1. Bizarre, that we are looking at steel rebar that was embedded in dirt and rocks.

That pile of rebar was cut from what was in the " ground" and discarded on the road surface.

The rebar that remains in the "ground" ...looks like it was dumped there, rather than carefully placed according to engineering specs.

1. Bizarre, that we are looking at steel rebar that was embedded in dirt and rocks.

That pile of rebar was cut from what was in the " ground" and discarded on the road surface.

The rebar that remains in the "ground" ...looks like it was dumped there, rather than carefully placed according to engineering specs.

2. Looking from the roadway, down to the railway level...

The removal of sections of the "new" abutment, and cutting of rebar.

Looks like new dcp bolts are currently being installed.

A new wall, or wall facing is being installed.

Quite extensive repairs to five year old work, I would sayThe removal of sections of the "new" abutment, and cutting of rebar.

Looks like new dcp bolts are currently being installed.

A new wall, or wall facing is being installed.

Question... Is the other support wall ( other side of track) going to get the same treatment?

Question. If Kiewit can't " build it right the first

time"... and leaves hazards on public roads in defiance of " Nobody gets

hurt"..and " Don't walk past an unsafe act"....then this whole

"warranty" repair process is an ugly joke.

The Province of BC deserves better than this.

Sept 2 2015 response

Hi Mike,

In

response to your observations of the CN wall work at Brandywine, these

repairs are being done as a result of the same documentation reviews

which instigated

the Pasco Road wall works. These are the only two walls on the Sea to

Sky corridor requiring such work, as a result of those reviews.

Further,

in regards to the work conditions you photographed, Kiewit’s crews have

informed us that all these areas were located behind a protective

fenced off

area; with signage in place to inform the public of an active

construction site. Additionally, the sections of rebar you came across

had actually just been removed and slated for disposal. Lastly, the cut

out section is not the abutment, rather they are pockets

cut into the CN rail crash wall, permitting installation of new

anchors. This also ensures that the new anchors do not interfere with

CN’s rail right-of-way.

I hope this email serves to provide some clarity to your observations. Thanks again for sharing.

Regards,

Deborah Tan

Concessionaire Manager

Lower Mainland District

Ministry of Transportation & Infrastructure

Ph: (604) 527-2289Added Sept 8 2015

MOT inspection reports and near the bottom...discussions on how/why Brandywine and Pasco issues were discovered

https://mail.google.com/mail/u/0/?ui=2&ik=c805bbfd5d&view=att&th=14fae96643d1e1d3&attid=0.2&disp=safe&zw

This highway project was opened just in time for the 2010 Winter Olympics.

It is often misquoted as costing 600 million.

The 2012 BC Auditor General report put the capital cost at 795 million ( before interest payments and maintenance costs )

Now, millions of "secret dollars" are being spent to fix errors in engineering and construction. American behemoth Kiewit, while hauling in 12 billion dollars a year...didn't "Get it Right the First Time" on the the Sea to Sky highway.

All the players in MOT and engineering have been very quick and very loud to point out that there are NO SAFETY ISSUES with the defective S2S walls and Brandywine CNRail overpass.

This, is supposed is to prevent any serious questioning of the faulty work done.

But, there are defects in engineering, inspection and construction...expensive problems. Expensive problems that have a root cause. Problems that need to be investigated through to a logical and complete conclusion. If the defects in the S2S project are fully investigated and the results made public, then it reduces the chances of repeating the errors.

( once fooled, but twice is our own damn fault )

The Province of BC paid top dollar for the Sea to Sky Highway upgrade.

MOT is now trying to downplay the discovery of faulty work and improper components in a complex project that is ultimately funded by the public.

Is it possible that MOT upper management is more interested in protecting the relationship with their American contractor, Kiewit...than they are in informing the BC taxpaying public about the current and future situation on the Sea to Sky Highway?

All the MOT staff and Minister Todd Stone are paid out of the public purse. The S2S project is paid for from the same seemingly bottomless purse. ( 795 million + maintenance + interest...puts the bill over 1 billion dollars. )

Fair answers to fair questions is not too much to expect, even in the twilight of accountability in this country. ( and the heyday of "spin" , denial and deflection. )

To finish

Inspect every damn inch of the Sea to Sky project. All 130 kilometers worth. Find and fix every defect, fault and oversight that affects the lifespan, structural integrity and "paid for" dollar value.

If the Province of BC was complicit, aiding or supporting shoddy work at taxpayer expense...for short term glory...then that is a whole other ball of poop.

2 videos that explain a bit about MSE walls.

The TxDOT video talks about the wall specs as it goes up. Kinda looks like Kiewit workers.

This video describes the general process of building an MSE wall.

Engineering report on why MSE walls under-perform or fail

MSE Wall Engineering - Kleinfelder

www.kleinfelder.com/kleinfelder/.../MSE_Wall_Engineering_TP.pdf

News stories, radio and television about the Sea to Sky defects...

CBC Radio interview ( click the little box on the right )

http://www.cbc.ca/m/news/

Global TV

Another retaining wall on the Sea-to-Sky needs repairs ...

Laila Yuile

Troubling photos spark Ministry of Transportation ...

lailayuile.com/.../troubling-photos-spark-ministry-of-transportation-inspe...sea to sky highway | No Strings Attached : Laila Yuile on ...

lailayuile.com/tag/sea-to-sky-highway/

North Shore News

Highways critic calls for audit - North Shore News

www.nsnews.com/news/highways-critic-calls-for-audit-1.1940767Vancouver Sun

BC Transportation Minister rebuffs NDP call for independent ...

www.vancouversun.com/technology/Transportation...call.../story.html

elbowing in for an interview.

Now that things are going wrong.....silence. Nobody home.

Sea to Sky engineering an amazing feat - Vancouver Sun

www.vancouversun.com/technology/engineering+amazing.../story.html

Sea-to-Sky Highway Improvement | MMM Group

mmmgrouplimited.com/projects/sea-to-sky-highway-improvement/Sea-to-Sky Highway Improvement Project - Kirk & Co ...

kirkandco.ca/project-profile/sea-to-sky-highway-improvement-projectSea-to-Sky Highway Improvement Project | Hatch Mott ...

www.hatchmott.com/projects/sea-sky-highway-improvement-project

Some examples of Sea to Sky highway retaining walls under construction.

Comments

Post a Comment